Index

- 1. A User-Oriented Approach to Performance

- 2. Tribology Research & Surface Microtopography

- 3. Building a Friction Framework for Players

- 4. The Challenge of Measuring Friction Accurately

- 5. Applying the Research: Engineering of VA-005 & CR-005

- 6. Weighted Kinetic Friction: Why Glide Changes Under Pressure

1. A User-Oriented Approach to Performance

Choosing the right mousepad is a personal decision. Every person's style, from mouse grip to hand pressure and mouse movement speed, influences what kind of surface feels right. Mousepads aren’t one-size-fits-all, especially at high levels of play. This understanding set the stage for Wallhack’s latest technical research on glass mousepad surfaces. We embarked on a research-driven mission to fundamentally understand why different glass surfaces yield different glide characteristics, so we could engineer new surfaces tailored to distinct preferences. The journey led us into the realms of tribology and surface microtopography (essentially, the science of friction and microscopic surface texture). By applying these sciences, we aimed to build a foundation of knowledge from which different glass surfaces could be engineered to deliver specific glide experiences, from speed to control.

2. Tribology Research and Surface Microtopography

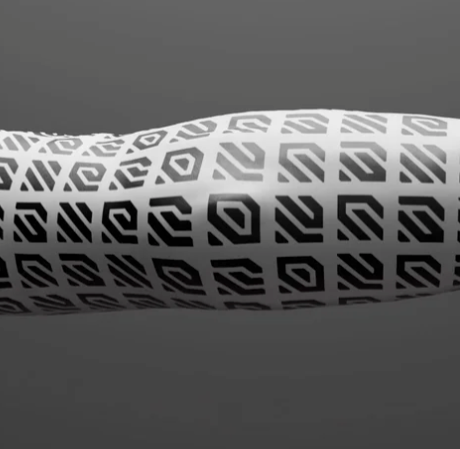

We first wanted to quantify and characterise the microscale texture of mousepad surfaces. Using high-resolution laser scanning and optical imagery, we mapped the microscopic landscape of countless etched glass surfaces. At this scale (measured in micrometres), the surface isn’t flat at all; it’s a complex terrain of tiny peaks, valleys, and patterns, as Figure 1 illustrates.

This microtopography directly influences friction and glide feel: different textures not only change the amount of actual contact area between the mouse skates and the glass, but also alter the dominant tribological mechanisms in play, which in turn affects the friction.

3. Building a Friction Framework for Players

In tribology, friction is defined as the resistive force, opposing motion, that arises when two surfaces in contact move relative to each other.

This force can be described mathematically as: Ffriction=μ⋅N

Where N is the normal force resulting from the object's weight (in this case, the weight of the mouse and the user's hand/forearm pushing down on top of the mouse) and μ is the coefficient of friction. This formula implies a linear correlation between μ and N. Thus, as more force is applied to the mouse (as N increases), the frictional force, Ffriction, rises linearly.

For mousepad users, the friction coefficient, μ, is the most important part of the equation, as this value quantifies the amount of resistance encountered by one specific combination of mousepad surface and mouse skates. Low values of μ will indicate low friction and high values result in high friction.

The are two main types of friction coefficients:

- Static Friction Coefficient (μS): The threshold of force needed to get the mouse moving from a dead stop. This is typically the highest friction value you’ll encounter, it defines the resistance felt at the very start of a movement. A lower μS means a less resistive start, whereas a higher μS provides more starting resistance.

- Kinetic Friction Coefficient (μK): The friction during steady mouse movement. This defines how resistant the glide feels once the mouse is in motion. A low μK produces a fast, effortless glide, whereas a higher μK means you feel more resistance while the mouse is moving.

During our research, we also introduced a third metric that differs from conventional tribological terms:

- Weighted Kinetic Friction (μK-W): The same as kinetic friction but measured under higher mouse pressure (simulating when a player presses down harder, for example when trying to stop the mouse).

This trio of friction coefficients gives a comprehensive picture of a mousepad’s glide behaviour: static friction determines the start-up resistance, kinetic friction defines the resistance of sustained motion, and weighted kinetic friction indicates how the kinetic friction increases as more pressure is applied to the mouse.

4. The Challenge of Measuring Friction Accurately

Not only is the relationship between a surface’s microtopography and its friction profile complex, but so is the science of measuring friction itself. Many factors can affect friction measurements. For example, important variables include:

- Surface texture: the etched glass surface finish or texture being tested.

- Skate material: the mouse skate material and its surface condition.

- Test speed: the sliding speed during testing.

- Number of skates: the number of mouse skates used on the mouse.

- Skate arrangement: the pattern/placement of skates on the mouse.

- Skate wear: the wear state of the skates (new vs. worn-in vs. worn-out).

- Distance of movement: the length of the testing distance (how far the mouse is moved during a test).

- Path geometry: the path of movement (whether the mouse is moved in a straight line or along a curved path, such as circles).

- Environment: temperature and humidity.

- Normal load: the downward pressure on the mouse.

All of the above factors affect friction measurements, so it is quite difficult to ensure that friction testing is consistent and that tests are comparable. Our goal was to control all of these variables except for the one being tested (such as the pad’s surface or the skate material). Even something as simple as the amount of use on a set of skates can significantly alter friction – enough to ruin the scientific integrity of an experiment.

Although standard friction testing machines exist, none of them met our requirements for testing mousepads and mouse skates. Furthermore, most friction testing equipment is built to ISO or ASTM standards meant for testing plastics and films, not glass. These issues led us to develop Wallhack’s own proprietary friction-testing machine and methodology. This ensured reliable friction measurements throughout the development of the 005 series pads.

5. Applying the Research: Engineering of VA-005 & CR-005

With this extensive research into the science behind etched mousepad surfaces for glass, specific surfaces could be developed. This resulted in two new surfaces for Wallhack’s 5th generation of glass mousepads, the VA-005 and the CR-005.

These surfaces each take a completely different approach to the micro topography of the surface, in order to create two distinct friction profiles and glide experiences.

The VA-005 features a microscopic landscape of pyramid-like structures. These structures are specifically designed to reduce the amount of friction between the glass and mouse skates. There are few points of contact, and the points of contact are non-sharp in nature. This limits friction in two ways. First, less real contact area means fewer molecular bonds and thereby less adhesive friction. Second, the hard glass pyramid tips are not very sharp, in fact the angle of the walls of the pyramids are very shallow. This 3d micro-geometry limits friction caused by asperity deformation, or ploughing, which is a form of frictional force that happens when two surfaces physically deform each other, or interlock, like a saw cutting through wood, or like the tread on shoes interlocking with the ground. In this case it just happens at a much smaller scale.

The CR-005 surface on the other hand, has been precisely developed for control. Its microtopography consists of a dense clustering of concave structures resembling tiny craters. This microtopography limits real surface area contact, to create an overall smooth glide. However the ridges of each crater act as physical asperities, that increase friction stemming from tribological ploughing. This results in higher static friction, as well as high kinetic friction, creating a controlled, stable glide. Furthermore, these microscopic asperities impress more and more into the mouse skates as you put more pressure on the mouse, giving it a high level of weighted kinetic friction (see next section, for a detailed explanation).

6. Weighted Kinetic Friction: Why Glide Changes Under Pressure

As described earlier, the fundamental properties of friction explain that there should be a linear correlation between how much downwards force is applied to the mouse and the friction between the skates and the surface of the mousepad. However, this principle is not always true in practice, because it assumes the friction mechanisms remain unchanged even as pressure increases. While this might hold for flat, rigid surfaces such as steel, it is not always true for softer materials like the polymers that mouse skates usually are made from.

In the case of an etched mousepad with fine microscopic structures and polymer mouse skates, the way the soft polymer surface interacts with the microtopography of the glass changes fundamentally under higher pressure. Thus, the traditional understanding of linear friction coefficients gets slightly warped.

To understand this, let's consider two scenarios:

Scenario 1: Using the CR-005 surface with PTFE skates under a light applied pressure (similar to normal use). As shown in Figure 6, when a light normal force is applied to the mouse, the skates remain mostly on top of the CR-005 surface, ‘not pressing into the microscopic surface asperities, high-friction ridges. Here, it is mostly the molecular adhesion frictional forces acting, not ploughing or interlocking between surface asperities.

Scenario 2: Using the same CR-005 surface and PTFE skates under a high applied pressure (similar to pressing down when trying to stop the mouse). As shown in Figure 6, the hard glass surface presses much deeper into the softer PTFE skates. This introduces a completely different friction mechanism, since the glass is now physically pressing into the soft PTFE at a microscopic scale. In turn, adhesion is no longer the dominant friction force, the ploughing of the glass micro-asperities in the soft PTFE is now the most relevant frictional force. This increases the coefficient of friction itself, the more weight is put on the mouse.

The difference in how frictional force is generated in these two scenarios means that the coefficient of friction (μ) is no longer constant; the frictional force is now produced by fundamentally different mechanisms as the normal force increases. In other words, for some etched glass surfaces, both the static and kinetic friction coefficients can change as more pressure is applied – even though textbook theory tells us the coefficient of friction should stay the same.

But what does this mean for the glide experience? Essentially, surfaces whose friction coefficients increase as you put more and more pressure on the mouse (i.e. having a higher weighted kinetic friction in comparison to the normal kinetic friction), will feel like they get an extra boost of stopping power, beyond what you’d expect just from the added pressure on a typical hard surface.